Why Stud Finder works may be a unique product that uses strong magnets for a metal stud finder.

Are you planning to buy a stud finder?

If yes, then do not waste any time. Read this article carefully. It will tell you about the benefits of stud finder products and also about the negative points. So, just go ahead…

Why stud finder works?

The product is designed to use a single-action trigger for easy results. This product has been used as a doorknob opener for years but was modified for use as a magnetic stud finder by adding powerful Magnets.

One important thing you need to remember is that the stud finder, regardless of its type, needs to be precise and provide accurate results so that you do not need to drill again.

Magnetic stud finder works on three major levels for fast and easy track of screws and nails. Firstly, it is very fast and simple to use since it does not require drilling. Secondly, it is safe to work with, especially if the locating includes drilling.

Thirdly, it can easily locate nails, screws, studs, and bolts without damaging them.

It is designed for all types of metals such as iron, aluminum, steel, brass, bronze, and stainless steel.

Why Stud Finder works is we first need to dig deeper into the stud finder's advantages and disadvantages, let us understand first how it works.

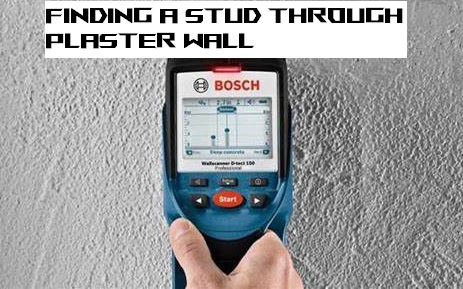

Magnetic sensors (which are also called magnetic indexes) are placed near the wall studs or joints. The magnetic sensors are either placed on drywall or painted walls.

This drywall sensor will detect metal and not plaster or other kinds of wallpaper.

So if drywall is detected, the stud finder's magnetic properties will sense for metal. In this case, a computer chip is used to detect metal. Once detected, it will automatically move the scanner closer until it finds the location of studs or joints.

There are basically two kinds of stud finders.

First, there are electronic ones and the second is the traditional ones. Electronic ones work by using two electromagnets and one electronic sensor.

Traditional works by using a wheel that rotates and a magnetic field. Since modern stud finders use an electronic system, the traditional method of working with drywall and painting must be modified.

Modern stud finders now come in different sizes. Some are even able to detect smaller joints and studs. If you plan on installing the device on your own, make sure to purchase the correct size and materials.

Usually, it would take you, two people, to install one-inch-thick materials. Most professional companies can provide assistance for those who are having problems installing it.

Basically, a stud finder works by moving relative to any stationary object that causes it to move.

Different types of materials may require different methods of movement. For instance, the metal stud finder works best in areas with varying widths because it is able to detect thicker areas. Also, different types of beams like steel or concrete may require different methods of detection based on their direction and thickness.

Another type of metal stud finder is the hammer-head stud finder that is used to locate metals like aluminum and copper.

Usually, this kind of finder has either a hard plastic drum or a coil spring that holds a metal disc or a magnet. When you place the metal stud finder on the joint where the two metals touch, the magnet will cause the metal disc to rotate and thus, will produce marks on the surface of the metals.

To make sure that the marks are level, you will need an angled cut of a metal screw so you can place the magnet over the marks.

The magnetic stud finder works more accurately in areas where the ground is moist or wet. Therefore, it is mostly used in places where the humidity is high. It uses coils or magnets as its source of power.

These work best on damp or wet surfaces because they have little friction and hence produce less wear and tear. Also, they are very quiet, so you don't have to worry about disturbing people when you use them.

The third kind of stud finder is the cordless sensor. This kind of tool works by taking a measurement of the area you want to locate, plugging it into a power supply, and then pointing the device towards the spot you want.

As soon as the device reaches the end of the area, the unit automatically points towards the wall and produces an electronic signal.

That lets you know where the wall is.

Because of its compact size, it is easy to mount and operate. You can also control the range of the signal by adjusting the sensitivity of the sensors.

The last type of stud finder is called the cordless screwdriver/stilet puller that works by using a screwdriver that has a magnet on the end. Instead of pulling up or pushing down on the surface, you can simply use your finger to pull up the nails without exerting pressure on the surface.

The magnet will also allow you to find screws and bolts without having to actually reach for them.

To locate the screws and bolts, you simply place your finger on the front of the nut and the magnet will guide your fingers right to the hole. It works much like a screwdriver, and just about anyone with a screwdriver can perform this task.